Industrial laboratories are essential for maintaining high standards of product quality and ensuring the structural integrity of materials used in various industries such as automotive, aerospace, petrochemical, and civil engineering. These labs conduct thorough testing and inspection processes to assess the physical and mechanical properties of materials, detect flaws, and verify compliance with strict quality requirements. By using advanced and reliable testing methods under certified and standardized conditions, industrial labs help manufacturers achieve consistent performance, safety, and durability in their products. This rigorous quality control is vital for meeting regulatory standards and customer expectations across multiple sectors.

Hardness testers evaluate material resistance to deformation using methods like Leeb (portable rebound), Rockwell (depth of indentation), Brinell (ball indentation), and Vickers (diamond-shaped indentation). Ideal for metals, plastics, and composites, our testers offer digital readouts, automatic loading, and multi-scale compatibility for lab and field applications.

Types : Leeb, Rockwell, Brinell, Vickers, Bench type, Portable

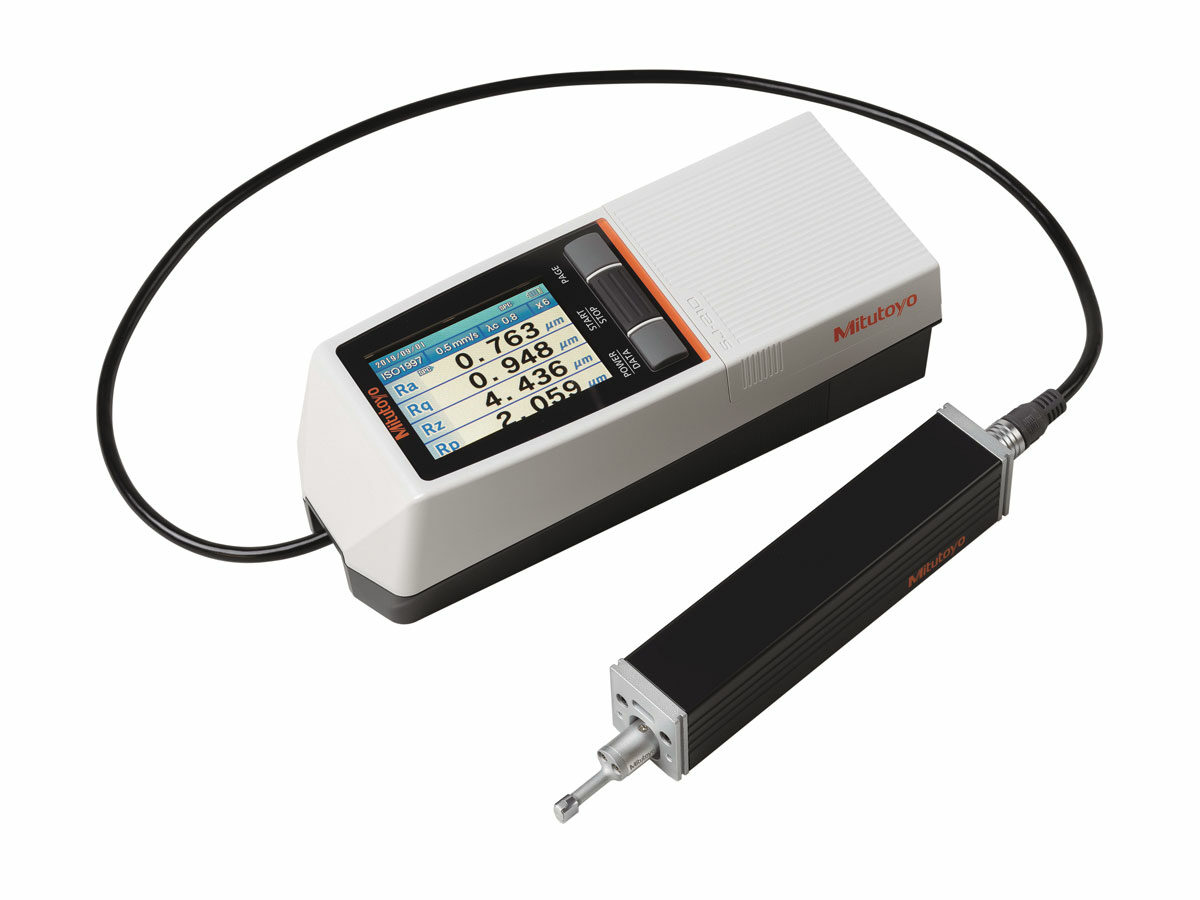

Surface roughness meters measure the texture and finish of material surfaces using contact (stylus) or non-contact (optical) methods. They quantify parameters like Ra, Rz, and Rt for quality control in machining, coatings, and manufacturing. Our meters offer handheld and benchtop options with digital data output.

Types : Portable, 3D Surface Profilers, Non-contact optical profilers, Contact profilers

Ultrasonic thickness gauges non-destructively measure wall thickness of metals, plastics, and composites using high-frequency sound waves. Common in corrosion monitoring and pipeline inspection, our gauges offer digital displays, multi-echo modes, and data logging for high-accuracy measurements even through coatings.

Types : Standard, Precision, Coating, High Temperture

Flaw detectors or Non-Destructive Testing (NDT) Instruments use ultrasonic, magnetic particle, eddy current, or dye penetrant techniques to identify internal and surface defects in materials. Widely used in welding, aerospace, and infrastructure maintenance. Portable or benchtop models support precise defect mapping, ensuring structural integrity without damaging components.

Types : Ultrasonic, Magnetic, Dye Penetrant, Eddy Current, Radiographic

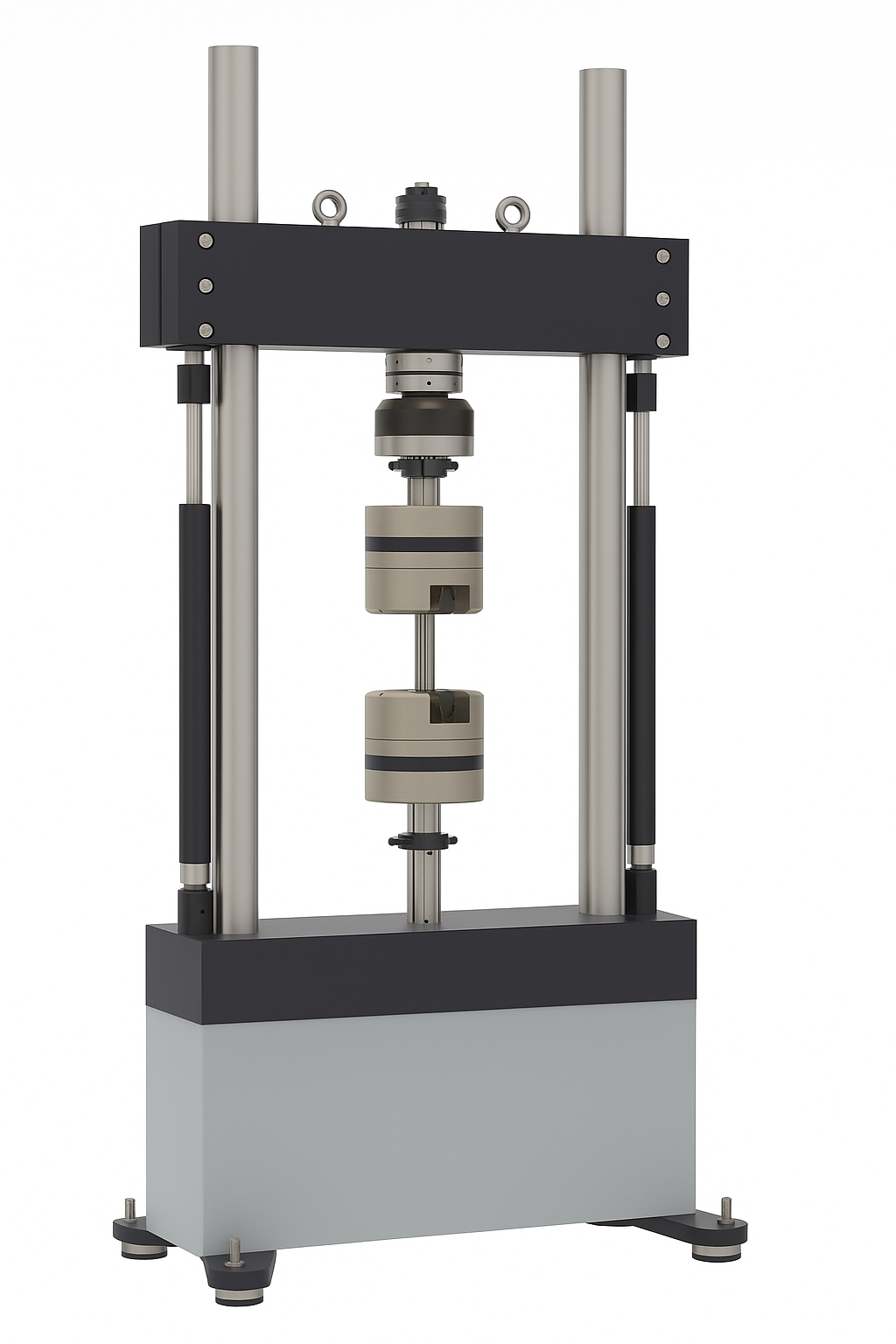

Tensile testing machines determine the strength and elongation properties of materials under uniaxial tension. Used in metals, plastics, textiles, and composites, our machines offer automated controls, digital load cells, and extensometers for accurate stress-strain analysis and material performance characterization.

Types : Universal, Single Column, Dual Column, Microtensile

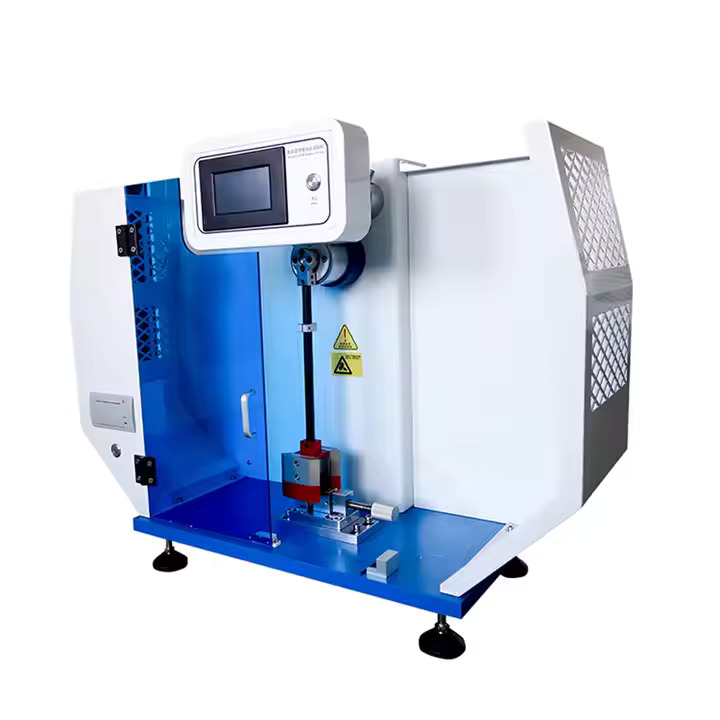

Impact testers evaluate material toughness by measuring energy absorbed during fracture using Charpy or Izod configurations. Common in metal, plastic, and composite testing, our systems offer automated pendulum mechanisms, digital energy readouts, and compliance with ASTM/ISO standards for impact resistance evaluation.

Types : Charpy, Izod, Instrumented, Pendulum, Drop Weight

Metallographic microscopes analyze microstructures of metals and alloys after sample preparation. Equipped with brightfield, darkfield, or polarized light, they help identify grain structure, phase distribution, and inclusions. Our models offer ergonomic design, high-resolution optics, and image analysis software for research and quality control.

Types : Upright, Inverted, Digital, Polarizing

OES systems analyze elemental composition of metals by exciting atoms and measuring emitted light spectra. Ideal for alloy identification, trace metal detection, and quality assurance, our OES units offer fast, multi-element detection with arc/spark sources, automated sample handling, and spectral libraries.

Types : Arc/ Spark, ICP, Potable

Coating thickness gauges measure paint, plating, or anodizing layers on substrates using magnetic induction or eddy current methods. Used in automotive, aerospace, and corrosion control, our gauges are available in handheld and bench models, providing non-destructive, precise layer measurements.

Types : Magnetic, Eddy Current, Ultrasonic, Combination

Fatigue testers simulate cyclic loading to evaluate a material's endurance over time. They assess failure points, life expectancy, and fatigue limits under various stress conditions. Our machines offer programmable load profiles, high-frequency operation, and real-time data acquisition for metals, composites, and polymers.

Types : Rotating, Axial Load, Resonant, Servo - Hydraulic

Our portable and bench hardness testers offer reliable solutions for on-site and laboratory testing. Compatible with Rockwell, Brinell, Vickers, and Leeb methods, they accurately measure surface hardness of metals, plastics, and alloys. Portable models enable quick field assessments, while bench systems provide higher precision and data logging.

Types : Potable Leeb, Bench Rockwell, Vickers, Knoop, Universal

Environmental chambers simulate temperature, humidity, and climatic conditions to test material performance and durability. Ideal for electronics, aerospace, and materials R&D, these chambers support programmable cycles and data monitoring for accelerated aging, stability, and stress testing across a wide temperature and humidity range.

Types : Temperature & Humidity, Thermal Shock, Altitude, Salt Fog

Corrosion testers evaluate material resistance against oxidizing environments like salt spray, humidity, and acidic exposure. Common in coatings, automotive, and metal industries, our corrosion test systems feature programmable cycles, uniform distribution systems, and compliance with ASTM/ISO standards for reliable, reproducible results.

Types : Salt Spray, Electrochemical

Bend and flexural testers determine material strength, elasticity, and deformation under load. Used for plastics, metals, and composites, they perform 3-point or 4-point bending tests. Our machines deliver precise load-displacement data with automated controls and digital reporting for structural integrity assessments.

Types : Three point, Four point, Manual, Universal

Microhardness testers evaluate surface hardness of thin layers or microstructures using low-load Vickers or Knoop methods. Ideal for coatings, metals, and ceramics, our models offer high-resolution optical systems, precise force application, and automated data capture for in-depth materials analysis at the microscale.

Types : Vickers, Knoop, Automated, Manual

Thermal analyzers such as TGA (Thermogravimetric Analysis) and DSC (Differential Scanning Calorimetry) study material stability, composition, and thermal transitions. Used in polymers, pharmaceuticals, and chemicals, these systems provide precise temperature control and detailed heat flow or mass loss data under controlled conditions.

Types : Thermogravimetric (TGA), Differential Scanning Calorimetry (DSC), Simultaneous, Modulated

Digital calipers and micrometers offer high-precision dimensional measurements of internal, external, and depth features. Widely used in QC labs and machining, they provide easy-to-read digital displays, metric/inch switching, and data output options, ensuring accurate, repeatable results for engineering and production environments.

Types : Vernier, Inside & Outside Micrometers, Depth Micrometers, Dial and Digital Models

Pressure and leak testers evaluate system integrity by detecting pressure drops or fluid escapes in sealed systems. Essential in HVAC, medical devices, and packaging, our testers feature digital gauges, programmable limits, and multiple test modes (vacuum, air, or water) for reliable leak detection.

Types : Hydrostatic, Pneumatic, Helium, Burst

Salt spray chambers simulate corrosive environments to test coatings and metal surfaces for rust resistance. Common in automotive, marine, and industrial sectors, our chambers provide uniform salt fog distribution, precise temperature control, and long-duration testing in accordance with ASTM B117 and ISO standards.

Types : Neutral Salt Spray, Acetic Acid Spray, CASS, Cyclic Corrosion

Vibration testers assess product durability under simulated transportation, operation, or environmental vibrations. Used in electronics, aerospace, and packaging, our systems support random, sine, and shock testing with programmable frequency, amplitude, and axis control for comprehensive mechanical reliability evaluations.

Types : Electrodynamic, Mechanical, Hydraulic, Environamental

Optical comparators project magnified profiles of machined parts to compare them against design specifications. Suitable for measuring complex geometries, they feature precision lenses, digital readouts, and overlay chart capabilities. Ideal for tool and die, aerospace, and precision engineering inspections.

Types : Horizontal, Vertical, Digital, Manual, Motorized

CMMs measure the geometric dimensions of objects using touch probes or non-contact sensors. Essential in manufacturing and QA, they deliver high-accuracy 3D measurements, reverse engineering data, and automated inspection routines, supporting CAD integration and statistical process control (SPC) systems.

Types : Bridge, Cantilever, Gantry, Portable

XRF (X-ray Fluorescence) analyzers determine the elemental composition of solids, liquids, and powders. Common in metallurgy, mining, and compliance testing, our portable and benchtop models offer rapid, non-destructive analysis with minimal sample prep, delivering reliable results for quality control and regulatory compliance.

Types : Benchtop, Handheld, EDXRF, WDXRF

Our MAP Gas Analyzer offers precision verification of gas composition within modified atmosphere packaging systems, ensuring optimal shelf life and product quality. Designed for high-speed sampling, it requires minimal gas volume and delivers oxygen or O₂/CO₂ readings with 0.01 % resolution. Models come with touchscreen interface, integrated data logging, and battery-powered portability, also supports mobile lab use or shop-floor QC. Ergonomic design includes a self-protecting needle pen and flow control warnings to prevent blocked sampling. Long sensor life and user-accessible calibration keep operating costs low.

Types : O₂-only analyzers, O₂/CO₂ combined analyzers, Table top gas analyzers