OxyTech is Saudi Arabia’s trusted provider of Medical Gas, delivering safe, pure, and reliable solutions to hospitals, clinics, laboratories, and healthcare institutions. We understand the critical role that Medical Gas plays in patient care, surgical procedures, emergency treatments, and laboratory operations. That is why we are committed to supplying high-quality products that comply with the strictest medical standards, ensuring safety, precision, and trust in every delivery.

We offer a complete range of Medical Gas products, carefully sourced, stored, and delivered under strict quality protocols to meet the needs of the healthcare sector. Our supply includes:

Oxygen (O₂) – For respiratory therapy, surgical procedures, and intensive care

Nitrous Oxide (N₂O) – Commonly used for anesthesia and pain relief

Carbon Dioxide (CO₂) – For surgical insufflation, medical diagnostics, and laboratory applications

Medical Air – Filtered, clean air supply for patient breathing support and equipment operation

Specialty Medical Gas mixtures – Custom solutions for specific medical and research requirements

All of our medical gas products are certified to meet international health and safety standards, with complete traceability and purity testing before delivery.

Healthcare and laboratory facilities across Saudi Arabia choose OxyTech for our proven expertise and commitment to excellence in Medical Gas supply:

Certified Medical Gas Quality – Every cylinder and container complies with international and Saudi Arabian regulations.

Reliable Supply & Nationwide Logistics – Timely deliveries to hospitals and clinics across all regions of the Kingdom.

24/7 Technical Assistance – Emergency supply and support whenever it is needed.

Industry Expertise – Years of experience serving the Saudi healthcare and laboratory sectors.

Strict Safety Protocols – From storage to transport, we follow advanced safety systems to safeguard both patients and staff.

With in-depth knowledge of local healthcare regulations and operational requirements, OxyTech has become a reliable partner for organizations ranging from large government hospitals to private medical centers. Our partnerships with healthcare providers and laboratories ensure uninterrupted supply, even in high-demand or critical situations. We also offer:

Rapid emergency delivery options

Expert consultation on medical gas selection and usage

Compliance support for facility inspections and audits

Our local presence in Saudi Arabia means we deliver not just products, but also trust, expertise, and personalised service designed for the Kingdom’s healthcare sector.

If you are looking for a reliable Medical Gas supplier in Saudi Arabia, OxyTech is ready to meet your needs. Contact our expert team for advice, quotes, or to arrange regular deliveries. Explore our product catalog and experience why leading healthcare facilities across the Kingdom trust OxyTech for their medical gas supply.

We are providing complete Set of Medical & Hospital gas system. MGS are engineered to provide a continuous and safe flow of essential gases like oxygen, nitrous oxide, compressed air, and vacuum across healthcare facilities. These systems include manifolds, oxygen generation plants, vacuum pumps, alarm systems, and pipeline networks. Designed in compliance with HTM, NFPA, and ISO standards, they ensure reliable gas delivery to all patient care areas. Built-in alarms, zone valves, and outlet safety features enhance operational safety and maintenance efficiency.

We are an expert team of Medical Gas Pipeline Systems. MGPS distribute life-supporting gases such as oxygen, nitrous oxide, medical air, and vacuum from a central source to various points-of-use across a healthcare facility. Constructed using medical-grade copper or stainless-steel pipelines, these systems ensure leak-free, continuous supply with optimal pressure control. Equipped with zone valve boxes, alarm panels, and gas outlets, MGPS comply with international standards like HTM 02-01, NFPA 99, and ISO 7396. They are critical for patient safety, surgical efficiency, and uninterrupted ICU or OR operations.

Medical Gas Manifolds are central supply units designed to regulate and distribute gases such as Oxygen, Nitrous Oxide, Medical Air, and Vacuum throughout healthcare facilities. Available in Automatic Manifold and Manual Changeover Systems, they ensure uninterrupted gas flow by switching between primary and reserve cylinder banks. Built with pressure regulators, non-return valves, and safety devices, they maintain stable output pressure. These manifolds comply with HTM and NFPA standards for reliability and patient safety.

Medical Gas outlets & Bed Head Units (BHU) We provide expert supply & installation for Medical Gas Outlets and Bed Head Units, which are essential point-of-use interfaces delivering Oxygen, Nitrous Oxide, Medical Air, and Vacuum directly to patients. Gas outlets are precision-engineered for secure, leak-free connections and comply with international standards (DIN, BS, AFNOR, or Ohmeda). Bed Head Units (BHUs) integrate medical gas outlets, electrical sockets, and lighting into a compact, wall-mounted system for ICU, recovery, and ward environments. These units enhance safety, accessibility, and space efficiency in patient care areas.

Medical gas cylinders are essential for storing and delivering life-saving gases such as oxygen, nitrous oxide, carbon dioxide, and medical air in healthcare facilities. Each cylinder is equipped with high-quality valves designed for secure sealing, pressure regulation, and safe gas release during use. These cylinders are used in surgeries, emergency care, and patient transport. Types of medical gas cylinders include portable, bulk, Aluminum, and high-pressure steel cylinders, available in various sizes.

Medical Cylinder Regulators ensure safe and accurate delivery of gases like oxygen, air, CO2 and nitrous oxide. Available in bull nose, pin index, and valve-integrated regulator (VIR) types, they include single-stage, dual-stage, and flowmeter-integrated options. Each unit comes with humidifier bottles to prevent dryness in patients, making them ideal for critical care, anesthesia, and respiratory therapy in healthcare environments.

We provides expert supply & installation of Medical Gas Alarm & Monitoring Panels, which are critical safety devices that continuously track gas pressure levels for medical gases and vacuum across the pipeline network. They feature high/low-pressure alarms, LED/LCD displays, and audible alerts to signal abnormal conditions. Available in area, zone, and master configurations, these panels enable real-time monitoring and rapid response during system failures. Designed to comply with HTM 02-01 and NFPA 99 standards, they enhance operational safety and patient care reliability.

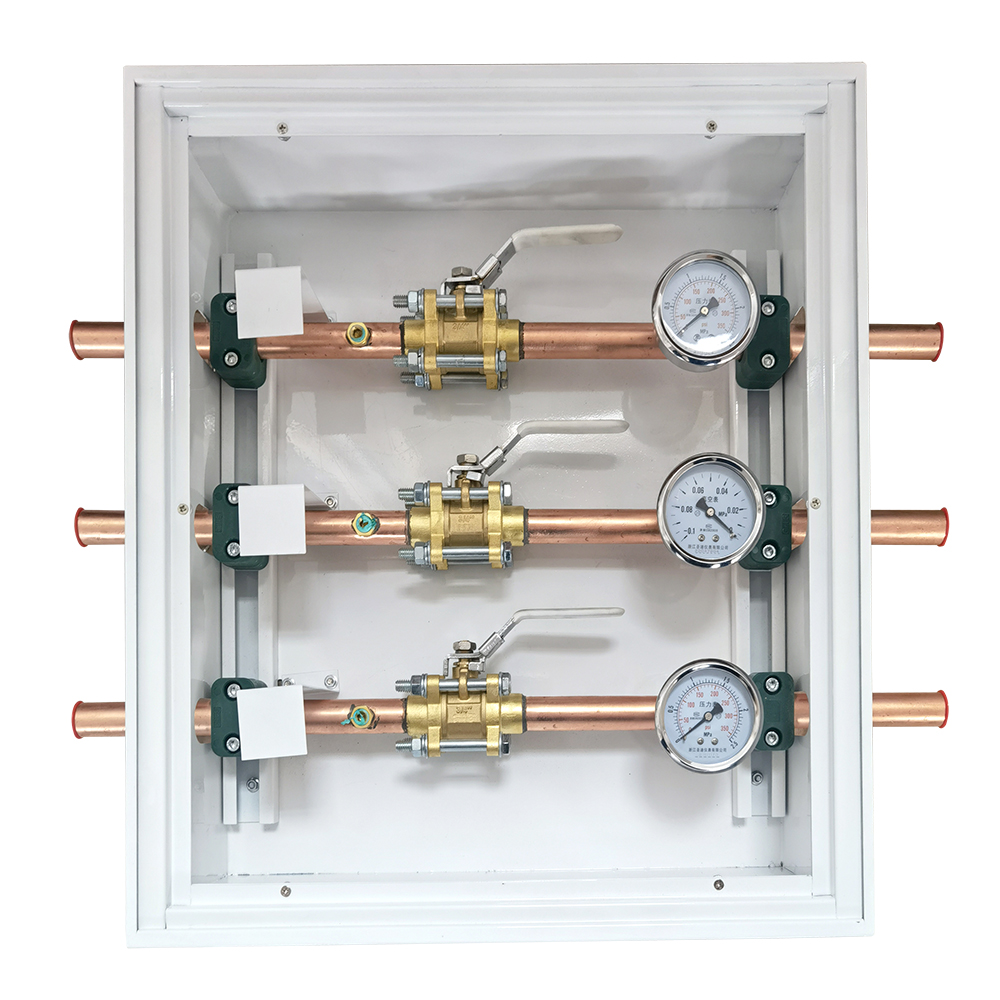

Area Valve Service Units (AVSU) are safety-critical components installed in medical gas pipeline systems to control and isolate gas flow to specific hospital zones. Each AVSU includes lockable ball valves, pressure gauges, and optional local alarm indicators for gases like Oxygen, Nitrous Oxide, Medical Air, and Vacuum. They allow quick shut-off during maintenance or emergencies without disrupting supply to the entire facility. Designed in compliance with HTM 02-01 and ISO 7396-1 standards, AVSUs enhance system safety and operational flexibility. Our company provides expert installation, maintenance, and servicing of AVSUs to ensure optimal performance and safety.

A Medical Air Plant supplies clean, dry, and oil-free compressed air for patient ventilation, surgical tools, and respiratory therapies. It typically includes duplex/triplex oil-free compressors, air dryers, filters, and bacterial filters to ensure medical-grade air quality. Designed for continuous operation, it maintains precise pressure control and meets HTM 02-01 and ISO 7396-1 standards. Our company provides expert installation, maintenance, and support services to ensure optimal performance and reliability. These systems are essential for ICU, NICU, operating theatres, and general ward applications.

A Medical Vacuum System provides a continuous and controlled source of suction for surgical, ICU, and emergency procedures. It typically consists of oil-lubricated or oil-free vacuum pumps, bacterial filters, receivers, and control panels. Designed to remove fluids, gases, and secretions safely, the system ensures hygienic waste disposal through a central pipeline network. Compliant with HTM 02-01 and ISO 7396-1, it plays a vital role in maintaining sterile and efficient clinical environments. Our company offers expert installation, maintenance, and support services to ensure optimal performance and reliability of your medical vacuum systems.

The Anesthetic Gas Scavenging System (AGSS) Plant is designed to safely collect and remove excess anesthetic gases from operating rooms to protect healthcare personnel. Our company provides comprehensive AGSS installation and maintenance services, including blower units, pipeline networks, receivers, and outlet ports connected to anesthesia machines. The system ensures proper ventilation, minimizes occupational exposure, and complies with HTM 02-01 and ISO 7396-2 standards. AGSS is essential for maintaining air quality and safety in surgical and recovery environments.

Our turnkey services encompass expert design, installation, rigorous testing, and commissioning of medical gas systems tailored for hospitals and healthcare facilities. Following HTM 02-01, NFPA 99, and ISO 7396 standards, we ensure leak-proof pipelines, accurate gas delivery, and safety system validation. Comprehensive testing includes pressure, flow, and purity assessments, along with alarm and valve functionality checks. This ensures a fully compliant, safe, and efficient medical gas infrastructure ready for clinical use.

Regular maintenance and compliance inspections ensure that medical gas systems operate safely and efficiently, adhering to HTM 02-01 and NFPA standards. Services include pipeline leak testing, pressure verification, alarm system checks, and preventive servicing of manifolds, compressors, and vacuum pumps. Comprehensive inspections identify potential faults early, minimizing downtime and ensuring continuous gas supply. Documentation and certification support regulatory compliance and patient safety.

Our Medical Oxygen Analyzer is a precision instrument designed for safe, accurate monitoring of O₂ concentration in medical gas lines and systems. It provides fast measurements down to 0.01 % increments, and is capable of verifying both gas composition and pressure (flow). Portable and battery-powered, available with different brands and models that can logs up to 500 past readings, supports multiple users, and exports data via USB or microSD for audit trails. Built with hygienic, user-friendly design, it’s ideal for hospitals, clinics, and mobile medical units.

Types : Oxygen-only analyzers, O₂/CO₂ combined analyzers