OxyTech is a leading Ultra High Purity UHP Gas Suppliers In Saudi Arabia, delivering world-class solutions to industries that demand the highest quality, reliability, and compliance with international standards. As industrial processes become more advanced, the need for gases with ultra-high purity levels has grown significantly across sectors such as electronics, laboratories, aerospace, healthcare, oil & gas, and petrochemicals. OxyTech stands at the forefront of this transformation, providing not only the purest gases available but also unmatched technical expertise and customer service.

Ultra High Purity (UHP) gases are specialty gases with impurity levels in parts per million (ppm) or parts per billion (ppb). These gases are essential for processes where even the smallest contamination can lead to defects, production errors, or compromised research results. For example:

Electronics Manufacturing – Semiconductor fabrication requires gases such as UHP nitrogen, hydrogen, and argon to prevent microscopic contamination.

Laboratory Research – Analytical instruments and chromatography rely on UHP gases to ensure precise measurements and reproducible results.

Healthcare & Pharmaceuticals – Oxygen and other medical-grade gases must meet exacting purity standards to protect patient safety.

OxyTech’s commitment to purity testing and certification ensures every batch meets ISO, ASTM, and regional GCC quality standards.

Saudi Arabia is rapidly diversifying its economy under Vision 2030, with strong investments in advanced manufacturing, renewable energy, health sciences, and petrochemicals. Each of these high-growth industries requires dependable access to ultra-high purity gases. OxyTech provides a crucial link in this supply chain—supporting research, production, and innovation while ensuring safety and compliance.

Being an UHP Gas Suppliers In Saudi Arabia, OxyTech maintains strong distribution networks in major industrial hubs such as Riyadh, Jeddah, Dammam, and Jubail. With strategically located facilities and logistics support, the company guarantees fast delivery and uninterrupted supply for large-scale industrial projects and sensitive research applications.

OxyTech supplies a comprehensive portfolio of ultra-high purity gases, tailored to the needs of different industries:

UHP Nitrogen (99.999% purity) – Widely used in electronics, laser-cutting, and as an inert atmosphere in manufacturing.

UHP Argon – Crucial for welding high-performance alloys, semiconductor production, and scientific research.

UHP Oxygen – Used in medical research, clean energy production, and specialty manufacturing.

UHP Hydrogen – Supporting chemical synthesis, electronics, and emerging hydrogen fuel projects in Saudi Arabia.

Specialty Gas Mixtures – Custom-blended to meet client-specific requirements in testing and calibration.

Each shipment is certified with purity analysis reports, ensuring complete traceability and confidence in quality.

OxyTech stands out in the Saudi market thanks to a blend of technical knowledge, operational excellence, and a customer-first approach. The company’s advantages include:

Uncompromising Purity Standards – OxyTech’s gases undergo rigorous testing to meet stringent specifications.

Advanced Storage and Handling – Cylinders and storage systems are designed to prevent contamination.

Compliance with International Standards – Full adherence to ISO quality management systems and safety protocols.

Technical Support – On-site consultancy for gas application optimization and safety training.

Reliable Delivery – Nationwide logistics ensure supply continuity for critical projects.

This positions OxyTech as not just a supplier but a long-term industry partner.

Handling ultra-high purity gases requires strict safety protocols. OxyTech invests heavily in training, equipment, and systems that ensure safety for personnel, customers, and the environment. All products are transported according to GCC regulatory requirements, ensuring compliance from production plants to end-user facilities.

The demand for UHP gases in Saudi Arabia is expected to increase significantly in industries such as:

Semiconductors and Electronics – Vision 2030’s technology focus requires an advanced local semiconductor supply chain.

Green Hydrogen Projects – Saudi Arabia is developing clean energy initiatives where UHP hydrogen purity is crucial.

Pharmaceutical Manufacturing – Medical-grade gases help boost local pharmaceutical production capabilities.

Research and Development – Universities and research labs require absolute precision in their experimental gases.

Our UHP regulators and high-purity valves are designed for precise pressure control and ultra-clean performance in demanding gas systems. Built with electropolished 316L stainless steel wetted parts, they ensure minimal particle generation and exceptional leak tightness (≤1×10⁻⁹ mbar L/s). Options include single-stage tied-diaphragm regulators, as well as manual, diaphragm-sealed, bellows-sealed, and pneumatically actuated valves. With pressure ratings up to 3500 psig and orifice sizes from 4 to 6 mm, these components are ideal for high-purity applications in semiconductor manufacturing, laboratories, and specialty gas delivery systems where safety, reliability, and purity are critical.

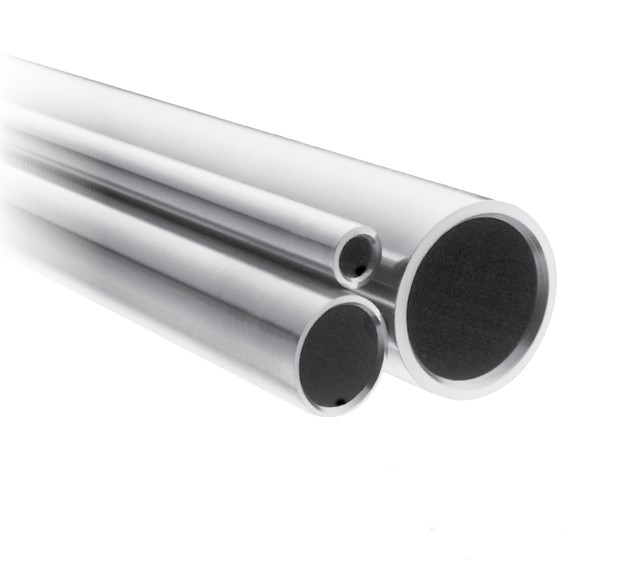

UHP orbital welded stainless steel tubing is engineered from 316L stainless steel, electropolished to Ra ≤ 0.25 μm, and cleaned/passivated to ASTM G93 Level A standards. Available in fractional (1/8″–2″) and metric (6–18 mm) sizes, tubing features orbital weld ready ends, pressure ratings up to ~5100 psig (1/4″ OD), and individual ISO Class 4 packaging with traceable test certification—ideal for ultra high purity gas and critical fluid systems.

Our UHP fittings are precision-engineered to meet the highest standards of purity and performance in critical gas systems. These include high-flow weld fittings, metal gasket face-seal connectors, and bulkhead/NPT unions, all manufactured from electropolished 316L stainless steel and assembled in Class-10 cleanrooms with Ra finishes down to 0.08 µm. Designed for ultra-high-purity and high-pressure applications, they ensure leak-tight integrity (helium leak-tested to 10⁻¹⁰ cm³/s), compatibility with orbital welding setups, and interchangeability with industry-standard components. Ideal for semiconductor, laboratory, and specialty gas delivery systems demanding cleanliness, reliability, and traceability.

UHP Automatic Switchover Panels ensure uninterrupted gas supply by automatically switching between primary and backup cylinders. Designed for ultra-high purity applications, they feature electropolished 316L stainless steel components, low dead volume, and high leak integrity. Ideal for semiconductor, pharmaceutical, and research labs where continuous, contaminant-free gas delivery is critical. Available in manual, semi-, and fully automatic models.

Our high-purity gas filters and submicron purifiers deliver ultrapure gas through 0.01 µm sintered metal, PTFE membrane, and coalescing filter media. These multi-stage systems remove particulates, oil, moisture, and trace impurities, achieving <1 ppb moisture and <1 ppt organics. Constructed from electropolished 316L stainless steel and VCR connections, they suit semiconductor, analytical, and laboratory gas systems, providing maximum purity and reliability in sensitive applications.