When it comes to high-precision gas delivery and handling, OxyTech stands out as a trusted and innovative Speciality Gas System Suppliers In Saudi Arabia. Backed by years of industry experience and technical excellence, OxyTech delivers customized gas system solutions to meet the demanding needs of industries such as petrochemicals, laboratories, pharmaceuticals, semiconductor manufacturing, and research institutions.

At OxyTech, we prioritize Engineering Excellence, Application Expertise, and Safety Compliance, ensuring every solution aligns with global best practices and Saudi Arabia’s industrial standards. Here's what sets us apart:

With a team of certified engineers and industry professionals, OxyTech has built a reputation for technical authority in speciality gas system design, installation, and maintenance. Our solutions are engineered with precision, reliability, and compliance at their core.

From gas distribution manifolds and control panels to purge systems, leak detection, and automated gas cabinets, OxyTech offers complete turnkey solutions tailored to your industry’s exact specifications.

Our systems are designed and installed according to international standards such as ISO, ASME, and NFPA. OxyTech’s solutions ensure maximum operational safety, system integrity, and long-term performance.

As a leading speciality gas system supplier in Saudi Arabia, we combine deep local market knowledge with international best practices to deliver solutions that meet the unique demands of Saudi Arabia’s industrial and research sectors.

Oil & Gas

Chemical & Petrochemical

Semiconductor & Electronics

Healthcare & Pharmaceuticals

University Labs & R&D Facilities

OxyTech has proudly partnered with government labs, private research centers, and large-scale manufacturing plants across Saudi Arabia. Our clients trust us for our technical accuracy, responsive support, and unwavering safety standards.

Pressure Gas Cylinder Regulators are designed for precise control of pure, inert, and corrosive gases, making them ideal for calibration, high-purity applications, and controlled atmospheres. The compact, ergonomic design includes an ATEX-compliant handwheel for safe and easy operation. Regulators can be fitted with shut-off valves and feature integrated relief valves for added safety. Depending on the model, sealing materials include EPDM for brass and FPM for stainless steel, offering excellent chemical resistance and durability for critical gas delivery systems.

Types : Low & High pressure regulators, Single & Double stage cylinder regulators, Diaphragm, Piston & Bellow technology regulators, Acetylene Regulators.

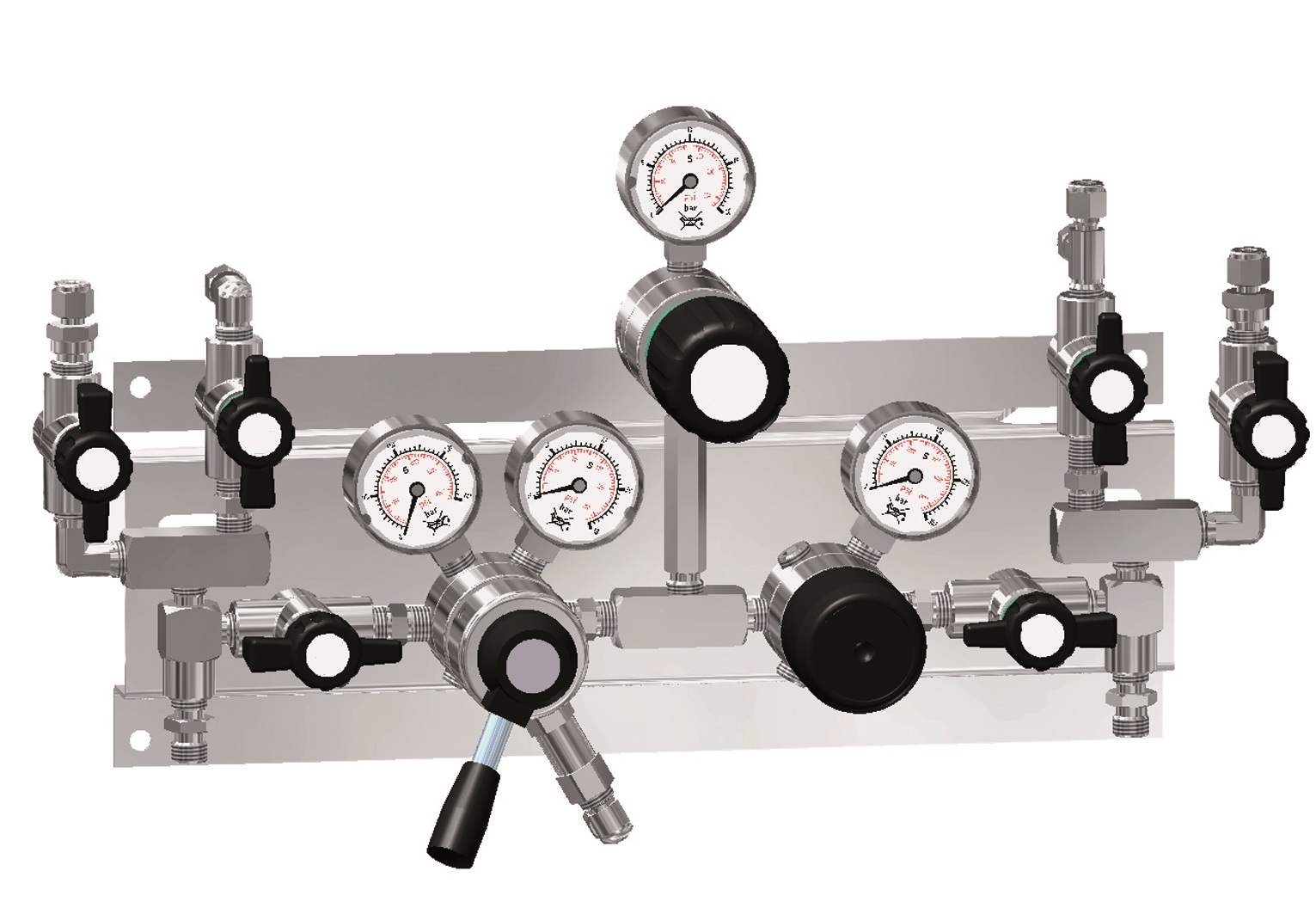

Supply and SOB for specialty gases ensure safe, uninterrupted gas flow for critical applications like labs, pharma, and high-tech industries. They automatically switch between primary and backup sources, maintaining stable pressure and purity. Up to 6 cylinders can be connected. All components come pre-mounted for quick installation. Optional features include a 1/4 turn shut-off valve, collection tube, and alarm box. Acetylene (AD) and Propane (PR4) versions are available on request for customized industrial gas solutions.

Types : Supply board with duo bloc, Automatic SOB with manual reset.

POU gas regulators for specialty gases are designed to deliver precise pressure control directly at the application site, ensuring gas purity and safety in critical environments like laboratories, research facilities, and industrial processes. These compact regulators minimize pressure fluctuations and contamination risks by being installed close to the end-use equipment. Ideal for high-purity, corrosive, or inert gases, they ensure consistent performance and reliability. Built with robust materials and high leak-tightness, they support analytical accuracy and process efficiency.

Types : Wall mounted / Benchtop POU, Diaphragm, Piston, and dome-loaded regulators.

Flow regulators are precision devices used to control and maintain a constant gas flow rate, with a set pressure. They are essential in applications involving specialty and high-purity gases, ensuring stable and accurate gas delivery for laboratory, analytical, and industrial use. Installed at the point of use, these regulators help optimize gas consumption, improve safety, and maintain system efficiency. Built in relief valve with corrosion-resistant materials, they offer excellent leak-tightness and durability, even with reactive or corrosive gases.

Types : Diaphragm, piston, and dome-loaded regulators.

Line valves are used to isolate or control gas flow in specialty and high-purity gas systems. Designed for leak-tight performance and long-term reliability, they help maintain system integrity and safety in applications such as laboratories, semiconductors, and industrial gas lines. Springless diaphragm line valves offer minimal particle generation and are ideal for ultra-high purity environments. O-ring and diaphragm line valves provide reliable sealing and precise shut-off for corrosive and inert gases. These valves are built from corrosion-resistant materials and ensure consistent performance under various pressure conditions.

Types : Manual, pneumatic, springless diaphragm, and O-ring diaphragm line valves.

Bellow valves are high-integrity shut-off valves designed with bellows sealing to ensure excellent leak tightness, especially for sensitive or hazardous gases. Suitable for low-pressure applications at ambient temperature, they are ideal for handling vacuum, pure and ultra-pure gases, combustible, oxidizing, toxic, corrosive, radioactive, and noble gases. The bellows design eliminates dynamic seals, minimizing the risk of leaks and contamination. These valves are commonly used in laboratories, semiconductor manufacturing, and critical gas systems.

Types : Manual, pneumatic, angle, and straight-through configurations.

Check valves are safety components designed to allow unidirectional flow and prevent backflow in gas and fluid systems. Engineered for ultra-high purity (UHP), high pressure (HP), and cryogenic applications, these valves ensure process integrity and system protection. They are compatible with a wide range of gases, including pure and ultra-pure, combustible, oxidizing, toxic, corrosive, radioactive, and noble gases. Featuring a replaceable spring and plug, they offer easy maintenance and long service life. Check valves are commonly used in laboratories, semiconductor, and industrial gas distribution systems.

Types : Inline, angle, high-pressure, cryogenic, and spring-loaded check valves.

Solenoid valves for gas are electromechanical devices used to control the on/off flow of gases in automated systems. Ideal for combustion systems, HVAC, laboratories, filling stations, gas distribution panels and process automation. Available in direct-acting, pilot-operated, and semi-direct (assisted-lift) configurations, they offer fast response, high flow capacity, and efficient operation under varying pressures. Engineered from stainless steel and brass with NPT or flanged connections, these valves ensure safety-rated performance up to high pressures.

Types : Pneumatic or Electrical control solenoid valve, Direct acting, pilot operated, and assisted lift models.

Cylinder connectors ensure safe and reliable connections between gas cylinders and equipment such as regulators, supply boards, or switchover boards—either directly or through flexible hoses or pigtails. They are designed for high-pressure and specialty gases and follow international standards like AFNOR, DIN, BS, CGA/DISS, NEN, JIS and UNI for various gases like oxygen, argon, air, helium, acetylene, nitrogen and mix gases.

Gas cylinder holders are designed to safely store single or multiple gas cylinders in designated areas. Wall-mounted and equipped with adjustable fixing belts, they securely hold cylinders in place to prevent tipping or movement. Multiple holders can be installed side by side for organized and space-efficient storage.

A low gas pressure alarm box is a safety device designed to monitor gas supply systems and alert users when pressure drops below a set level. It features a loud buzzer and a bright LED panel for instant visual and audible alerts, ensuring prompt response. Ideal for medical, industrial, and laboratory gas applications, it enhances safety by preventing supply interruptions. Available in wall-mounted and panel-integrated versions.

Contact pressure gauges (inductive gauges) are spare parts used with regulators, points of use, supply boards, or switchover boards to monitor and signal pressure levels. Available in sliding or inductive contact versions, they provide reliable pressure feedback. These gauges come with vertical or rear mounting options and are typically configured as Normally Open for easy integration into control systems.

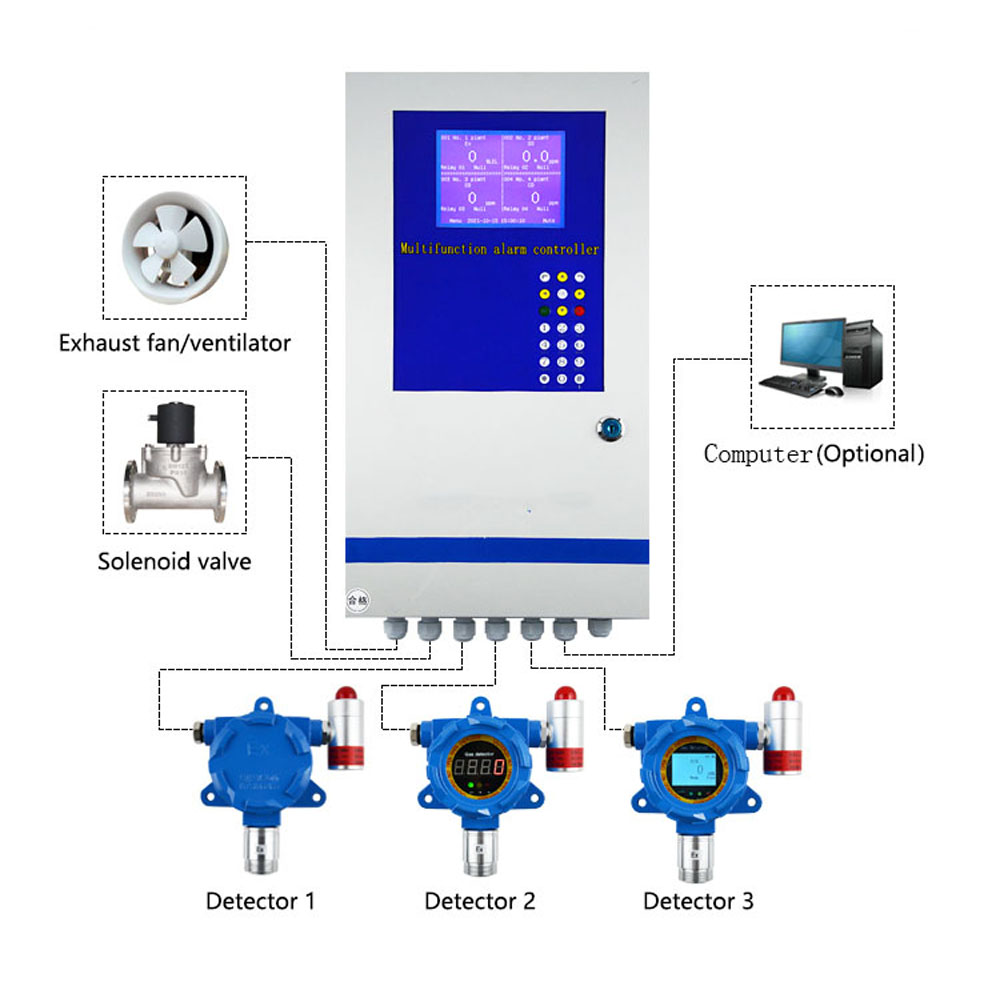

This system is a comprehensive safety solution designed to detect and respond to hazardous gas leaks in real-time. The system integrates high-precision gas leak sensors with a smart control panel, alarm box, and ventilation exhaust system to ensure rapid detection and effective evacuation of gases. In case of a leak, the system activates audible and visual alarms while triggering a solenoid valve for automatic gas shut off. Ideal for industrial, commercial, and residential gas safety applications.

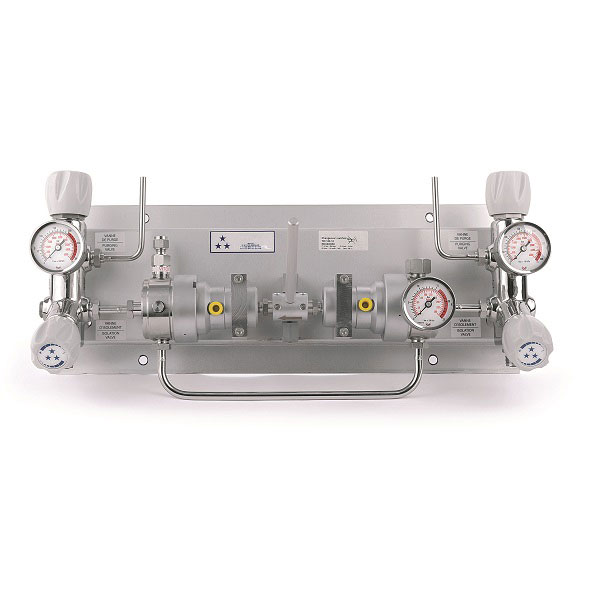

Gas extension boards are designed to connect multiple cylinders to a supply or switchover board from both sides, increasing gas availability and minimizing cylinder changeovers. Their integrated design reduces potential leak points, ensuring enhanced safety and efficiency. Available in left or right side configurations, they improve workflow and system uptime, making them ideal for high-demand gas applications in labs and industrial setups.

Gas cylinder hoses and pigtails are flexible connectors designed to safely transfer gases from cylinders to supply or switchover boards. Made from high-quality materials like electropolished stainless steel or PTFE-lined tubing, they offer excellent corrosion resistance and maintain gas purity. These hoses are pressure-rated, leak-tested, and available in various lengths and end fittings to suit specialty, industrial, and medical gas applications.

Our Specialty Gas Tubes and Pipes are precision-engineered from premium seamless stainless steel (316/316L) and chrome plated finishes, available in sizes ranging from 1/8″ to 1″ OD (3–25 mm). We offer a comprehensive selection—including fractional, metric, 6 Mo (254, AL6XN), and UHP electropolished tubes—meeting ASTM A269, A213, and EN 10216 5 standards. Ideal for ultra clean, high pressure gas delivery in semiconductor, laboratory, and pharmaceutical systems, our tubes provide superior corrosion resistance, high working pressures, and leak tight performance for critical gas applications.

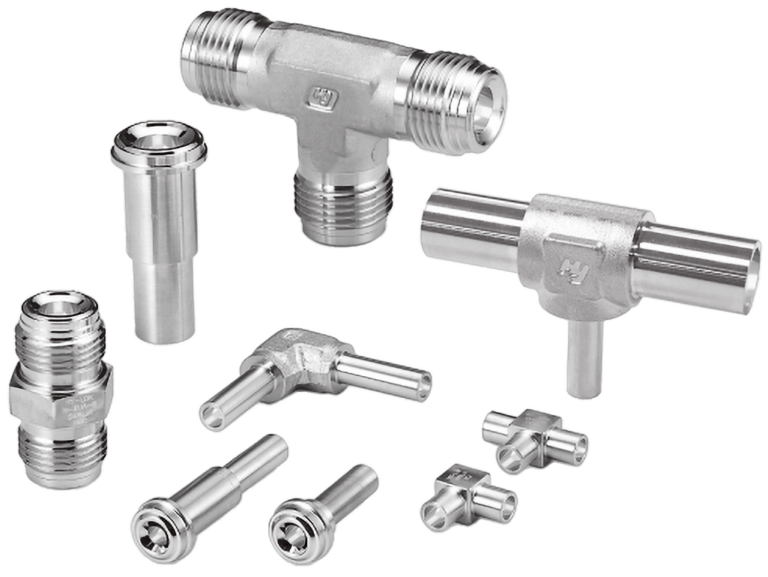

Gas system fittings and connections are essential for building safe, leak-tight gas distribution systems. Available in various types—such as tees, elbows, hex nipples, adapters, gaskets, and connectors—they support different sizes and pressure ratings. Precision-machined for reliability, they ensure high performance in demanding gas applications. Options include compression fittings, orbital weld fittings, and threaded connections, ensuring compatibility with specialty, industrial, and medical gases.